As a commonly used sealing component, O-ring wrapping may cause leakage problems in certain situations. The following are several analyses and Saibote’s response measures for this issue:

一、Quality issues with the sealing ring

The quality of sealing rings is a key factor in ensuring equipment sealing performance, extending service life, ensuring safe operation, and improving work efficiency. Therefore, when selecting and using sealing rings, one should fully consider their quality factors and choose high-quality products that meet the requirements.

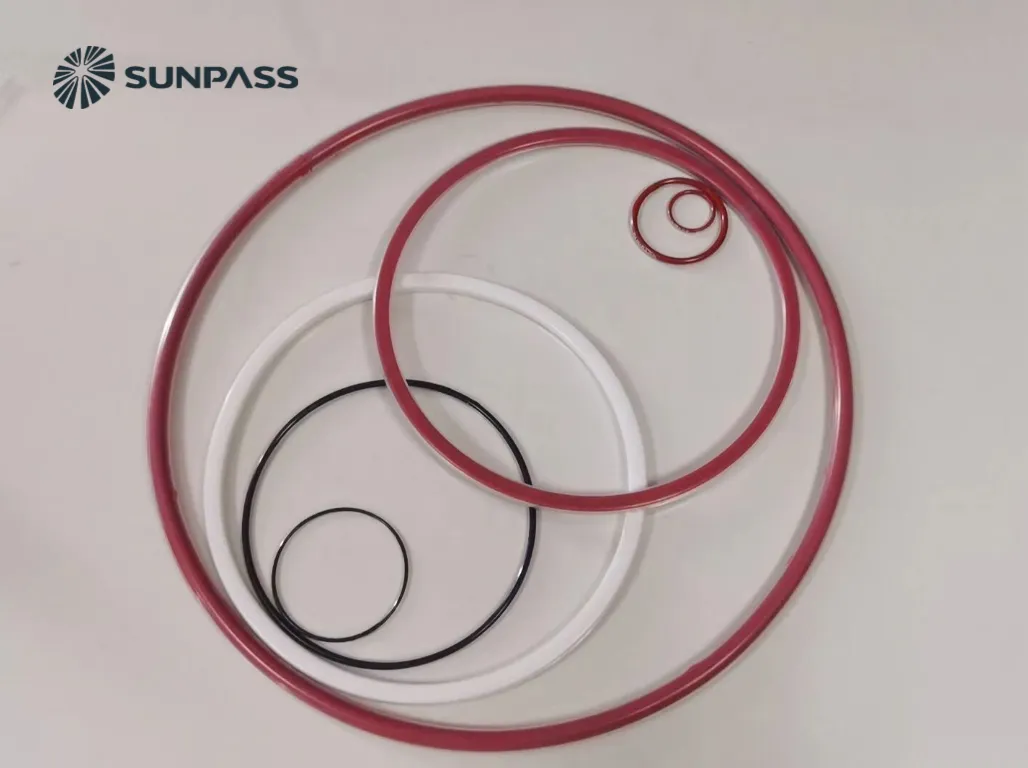

The O-ring produced by SUNPASS is made of Japanese Daikin brand material, which has excellent ductility and elasticity, and FEP material has extremely high light transmittance. The product undergoes five strict quality inspections before shipment and adopts precise manufacturing processes to ensure dimensional accuracy. We are committed to providing customers with high-quality O-rings.

二、Matching degree between workpiece and seal

Ensuring the matching degree between seal and workpiece is one of the key factors to prevent leakage

三、Precision of the workpiece

Insufficient precision and rough surface of the workpiece may cause damage to the O-ring during installation, leading to leakage.

四、Improper installation operation

四、Improper installation operation

Improper operation during the installation process is also an important cause of leakage.

SUNPASS has developed a detailed set of installation and operation guidelines based on domestic and international industry standards and professional advice from industry experts, aimed at reducing the leakage rate of O-rings in actual working conditions.

We sincerely welcome valuable opinions from industry experts to supervise the quality and stability of SUNPASS products, jointly promote the improvement of product quality, and reduce leakage rates.

Website:http://www.sunpass.biz